Depressed flat car moves happily to Palatka

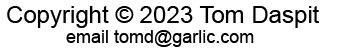

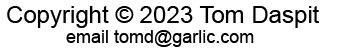

Lines were attached to the dryer in the hold, the blue crane handles were pulled back, and the dryer was swung out and loaded on the flatcar in the background.

Moving a large 337,530 pound dryer is as easy as eating apple pie – provided you do your homework.

Southern Railway recently transported the dryer on a depressed flatcar from Talleyrand Docks at Jacksonville, Fla. To a Georgia Pacific Corporation paper manufacturing plant in Palatka, Fla. The eight axle flatcar proved to be perfect for the oversized load.

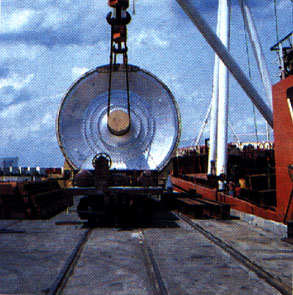

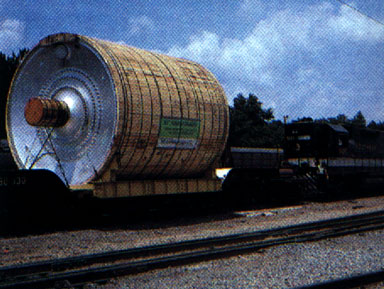

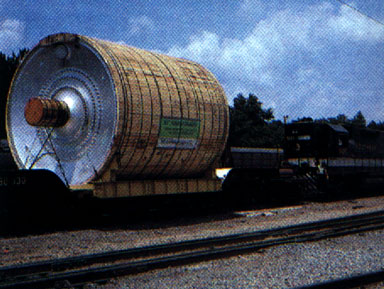

The dryer, called a Yankee Dryer and manufactured by the Beloit-Walmsley Company in Bolton, England, arrived in Jacksonville aboard Enak, a ship having its own crane. He Yankee Dryer is 23 feet long and 18 feet in diameter, actually 18 feet, five inches with the wood lagging added for protection.

Made of cast iron seven inches thick, and shined to a gloss, the Yankee Dryer is used to make tissue, a delicate operation in which wood pulp is shaved off into thin paper.

When Georgia Pacific expressed an interest in buying the dryer, the seller had to search for the most economical way to deliver this piece of machinery to Palatka. It was obvious that the dryer was too heavy and large to go on the highway, so the traffic manager of the Beliot Corporation of Beloit, Wis. contacted Norfolk Southern.

Because the dimensions f the dryer exceeded the existing clearance data base, Charles C. Smoot, V, SR manager, Clearances, Atlanta, asked SR's clearance engineering people to survey the line from Jacksonville to Valdosta, Ga., and an from there to Palatka.

The survey by Assistant Clearance Engineer F.D. Bess and Bridge Building Supervisor D.T. Jordan produced a detailed list of obstructions that would have to be removed if the dryer were to be shipped via Southern. The plan called for the relocation of 17 roadway signs, a railway crossing gate, and a railway signal; the removal and replacement of four switchstand targets and masts; and the removal of overhead tree limbs at 15 locations.

Yankee Dryer rests peacefully on SOU 50030

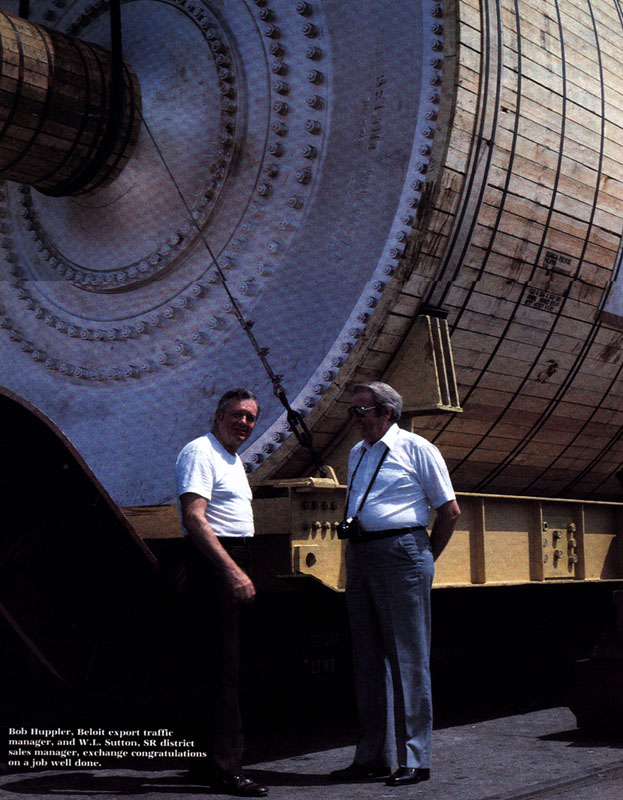

Meanwhile, in Jacksonville, W.L. Sutton, NS district manager, Sales, and L.M. Morgan, NS sales representative, worked up a rate with R.S. Basham, NS assistant manager, Pricing, Roanoke.

Plans for moving the dryer had to be as precise as possible because Georgia Pacific has an expensive crane on hire in Palatka to unload the cylinder.

As with all the plans of mice and me, there turned out to be one hitch. Between the time the line was surveyed and the day the ship arrived, a telephone company had placed a pole on SR's right of way. At the eleventh hour, the pole had to be removed before the load could move.

The special train transporting the dryer to Palatka consisted of a locomotive, the depressed flatcar and a caboose. All sidings and adjacent tracks were kept clear of moving traffic, and in many locations standing equipment was removed to permit unimpeded passage for the special train

When the special train reached obstructions, it slowed to walking speed. When there were no obstruction it surged ahead at 45 mph.

This is the second such dryer that SR has moved out of Jacksonville. In 1978, a dryer was shipped to a paper plant in Chapco, Ga. Southern is becoming a old had at this high, wide, and heavy business.

Yankee Dryer on here merry way to Palatka.

Photos by L.M. Morgan

The above pictures and text were taken from the July/August 1984 issue of

Norfolk Southern World Magazine.