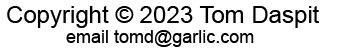

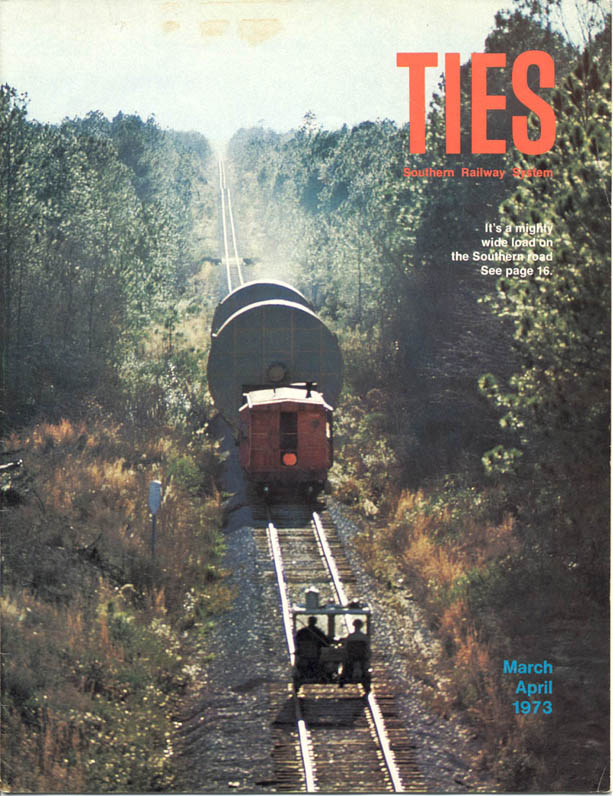

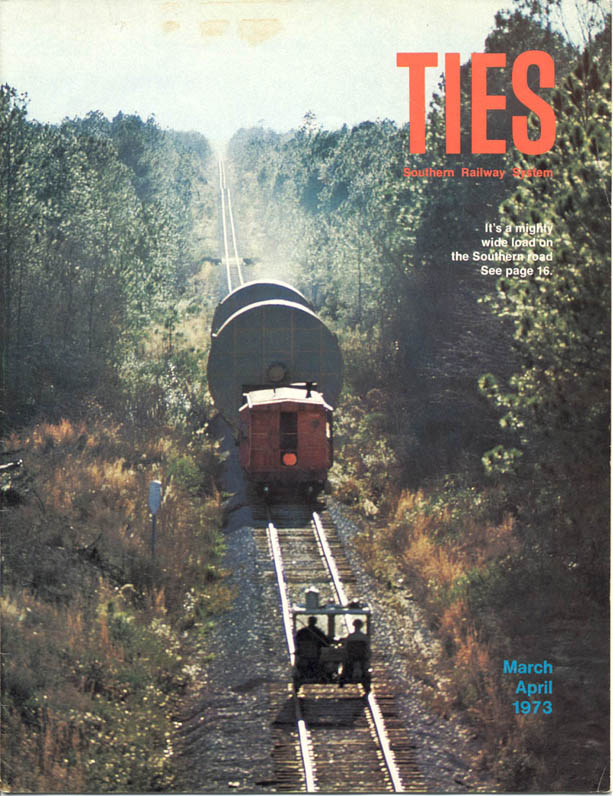

Three large paper dryers were shipped from Brunswick to Albany, Ga., via Southern Railway. The photograph, taken by Southern chief photographer Tom Emmons, shows the shipment as it approaches Douglas, Ga.

What would Procter & Gamble's Charmin Paper Products Company ship by rail from Brunswick to Albany, Ga., that is 30 feet long and 18 feet in diameter on a flat car rising 20 feet above, the rail? Answer: A paper dryer. Not one, but three!

The 160-ton cast-iron dryers are used in the paper manufacturing process at Charmin's plant near Albany. They Are the largest single pieces of equipment ever shipped to a Procter & Gamble or Charmin plant.

Manufactured at a Newport News, Va., shipyard, the dryers moved by barge to Brunswick. There, one of the world's largest mobile cranes lifted them onto special rail cars.

Southern conducted a field study to find the best route for shipment and identify obstacles to be removed. The 266-mile route selected took the dryers from Brunswick to Hazelhurst, Valdosta, and finally, Albany.

Along the route, railway signals and utility poles had to be relocated, grade crossing devices were temporarily removed, tree limbs were trimmed and trestles were strengthened.

The dryers had to arrive without damage or delay, either of which would have cost the Charmin Company expensive production time.

When all obstacles were cleared, Charmin built a mock-up of a dryer for a test run. It rolled along the route without difficulty,. as did the three real dryers.

Southern Railway moved this 160-ton paper dryer, and two others of equal size, from Brunswick, Ga., to the Charmin Paper Products Company plant at Albany, Ga., a distance of 266 miles.